NASA software sharing to save Army months – and millions

Connecting state and local government leaders

NASA has transferred more than 2,400 automated software procedures to the Army in an agreement expected to save $4 million in time and development costs.

NASA has transferred more than 2,400 automated software procedures, used to calibrate instruments for testing space vehicles and equipment, to the Army for use in calibrating its own test instrumentation.

The transfer of the software-based calibrations will cut the time the Army would have spent developing its own procedures, potentially saving the government nearly $4 million, according to the space agency.

"Sharing these procedures enhances the Army’s capability to perform more calibrations in less time, which leads to better customer support for Army operations and tests at a substantial savings for software development costs," said Gary Kennedy, NASA’s representative for the Metrology and Calibration Laboratory at NASA’s Marshall Space Flight Center in Huntsville, Ala.

The automated software procedures support test, measurement and diagnostic equipment. Both NASA and the Army run millions of calibrations every year to ensure their research and operations tests work safely and properly. Calibrations are only as good as the measurements and data collected, and the software ensures accurate and repeatable data, NASA said in a report on the project.

Of the 2,400 procedures NASA is transferring, about 1,700 were originally developed for the Space Shuttle program, and 300 were developed for general NASA use. About 400 are currently being used for NASA projects including the Space Launch System, a new deep exploration rocket managed by Marshall.

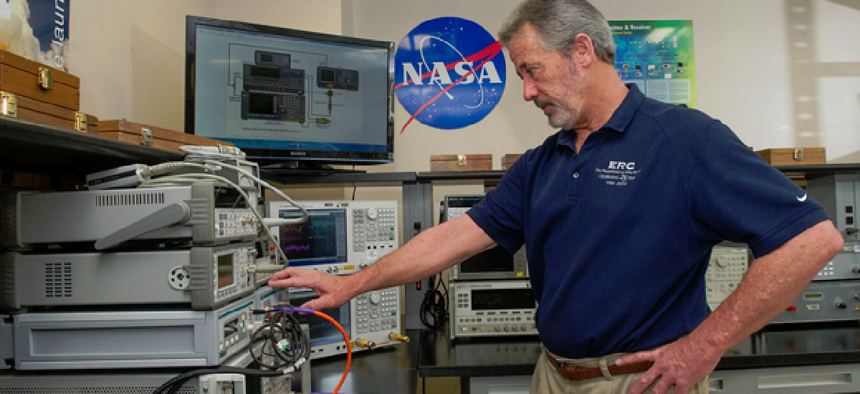

"The automated procedures control the instrumentation," said senior NASA metrologist Jeff Cheatham (pictured above), who spent 12 years developing the NASA procedures being transferred to the Army. "Human involvement increases the probability of errors [and] this ensures recorded data has a high level of veracity or stability with minimal variability from technician to technician."

Altogether the sharing arrangement will help the Army save months of development time and expense.

"We currently have a couple of software programmers writing procedures," said David Hargett, chief of the metrology engineering division at the Army’s Test, Measurement and Diagnostic Equipment Activity. "In a four-month window, they finished maybe 25. So, with access to this NASA capability, our numbers will increase to more than 2,400."

"In terms of automation and calibration, we’re a decade ahead of a lot of government agencies," said Kirk Foster, manager of NASA’s MCL lab. "We have unique facilities and equipment not found at other NASA centers or other government or commercial laboratories, so our technical and scientific capability is substantial."

Beyond the time savings, the procedures will help maintain the overall quality of the Army’s measurements.

"Cheatham spent hundreds of hours in trial and error, testing and validating data, while analyzing variability," said Kennedy. "His procedures include detailed images, in-depth descriptions and highlight the critical connections to help technicians eliminate errors during measurements."

Each procedure was vetted through a NASA software control system checking quality control and process integrity.

The Metrology and Calibration Laboratory continues to automate manual processes, eliminating human error and increasing efficiency. Other NASA centers have also benefited from Cheatham’s procedures, which are available to download through NASA web portals.

The Army will be the first non-NASA recipient, which NASA officials say could lead to interest from other Defense Department branches or other government agencies.

NEXT STORY: Spark fires up near-real-time big data