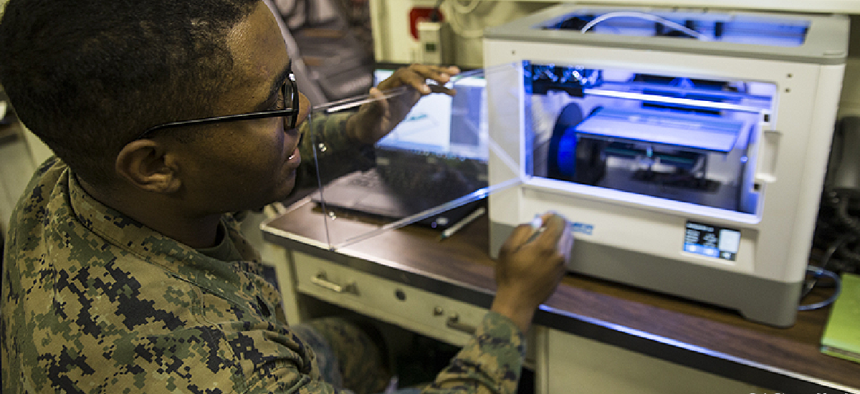

Marines’ 3D printing faces a ‘data problem’

Connecting state and local government leaders

The Marine Corps want to reorganize its repository of 3D printing designs and technical information into a data vault that makes it easier for the 300+ users to find the designs they need.

3D printing, or additive manufacturing, is gaining popularity with the military because it allows service members to quickly build spare parts for aging equipment in the field.

The Marine Corps keeps the 3D printing designs and technical data for more than 400 parts in a digital repository, but it wants to reorganize that information into a data vault that makes it easier for the 300+ users across the Corps to find the designs they need, according to a report in USNI News.

“What we have is a data problem,” said Kristin Holzworth, chief scientist at the Systems Command’s (SYSCOM) Advanced Manufacturing Operations Cell. Speaking at a WEST 2021 conference virtual session, she said that while there is plenty of data available for 3D printing, “it’s all disaggregated, and it’s unclear what we have, what we don’t have.” Plus, she said, “getting fleet access to what we do have can be quite difficult.”

The Digital Manufacturing Data Vault would be an enterprisewide advanced manufacturing repository, integrating additive manufacturing data from all the military services and the Defense Logistics Agency with program-managed technical data.

“It will enable fleet-wide accessibility and provide access to the entire Marine Corps enterprise and also for operations in multiple environments, including base, station, depot and expeditionary,” Holzworth said.

This year, Marine Corps units will have access to the X-Fab mobile facility -- a self-contained, 20x20-foot transportable shelter containing five 3D printers, a laser scanner and cutter and computer-aided design software system. Starting in fiscal 2022, each battalion will get a portable 3D printing kit, said Joshua Whitehead, maintenance officer at SYSCOM’s Amphibious Vehicle Test Branch.

Replacing critical parts with a 3D printer and access to designs is “much more expeditionary and more efficient for the Marine Corps,” he said.