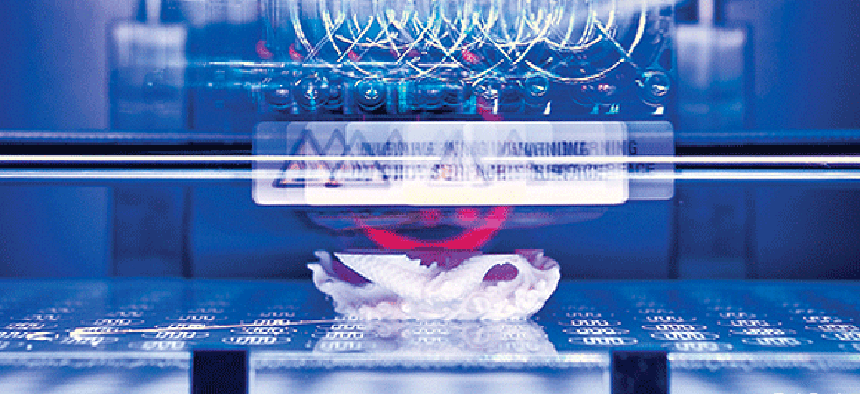

Army preps on-the-spot 3D printing process for the battlefield

Connecting state and local government leaders

The Army Research Lab and Purdue University develop a process that would let soldiers repair damaged parts on aircraft and ground vehicles on the spot.

In the latest example of how the military is learning to fix on the fly, the Army is developing a technology that will allow soldiers in combat zones to use 3D printing to repair damaged parts in aircraft and ground vehicles.

The new program, a joint effort between the U.S. Army Research Laboratory and Purdue University, combines the ABAQUS analysis tools with Python, an open source code that can be used to optimize structures.

According to a blog post from the U.S. Army Research Laboratory's Vehicle Technology Directorate at Aberdeen Proving Ground in Maryland, developing the ability to use 3D technology in the field to repair damage was an added bonus. The original goal was to create vehicles using a set of parts and topologically interlocked structures (TIS) using standard materials.

"The benefit for the soldier is an after-effect," Ed Habtour, a research engineer said in the post. "The TIS would provide an excellent energy absorption and dissipation mechanism for future vehicles using additive manufacturing. Subsequently, the soldier can print these structures in the field using additive manufacturing by simply downloading the model generated by the designer."

The segmented structures the lab is working on would be highly resistant to damage. Vehicles and airplanes made of them would be more resistant to heat, cracks caused by constant vibration and combat damage. They may even be better able to survive crashes. Once any of that damage does occur, a soldier could then diagnose the problem and use 3D printing to create replacement parts. If the outer skin of the vehicle were damaged, new parts could literally be printed and stuck onto the existing vehicle, making it as good as new.

"Sometime in the near future, soldiers would be able to fabricate and repair these segmented structures very easily in the front lines or Forward Operating Bases, so instead of moving damaged ground or air vehicles to a main base camp for repair, an in-field repair approach would essentially mean vehicles would be fixed and accessible to warfighters much faster at lower costs," Habtour wrote. "We want to change the conventional thinking by taking advantage of exciting materials and manipulating the structure based on the principle of segmentation and assembly."

The project is just among the latest military efforts to make innovative use of 3D printing. Last year, the Army added 3D printing capability to several of its Rapid Equipping Force labs in Afghanistan.

NEXT STORY: 3D printings new frontier: Rebuilding lost reefs