Army taps crowd for rapid, tactical tech solutions

Connecting state and local government leaders

The Army's Rapid Equipping Force partnered with Local Motors to develop ArmyCoCreate, an online platform that lets soldiers and civilians collaborate on Army solutions.

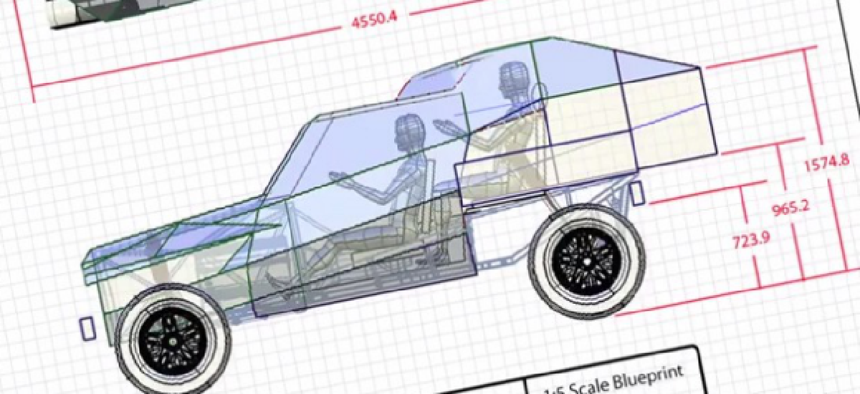

The Army recently completed a crowdsourcing project that took the development of a mobile command post from concept to working prototype in less than 60 days.

The Army’s Rapid Equipping Force (REF), which launched in 2002 to meet warfighter requirements in Afghanistan, aims to quickly field solutions for globally deployed forces. Lately, the REF has been tapping crowdsourcing techniques to speed up development. In August, REF partnered with Local Motors to develop ArmyCoCreate, an online platform that lets soldiers and civilians collaborate on Army solutions. Local Motors, a Phoenix, Ariz., company, designs and builds vehicles using open-source principles.

The ArmyCoCreate platform launched in October 2013 and was soon put through its paces. Soldiers and the online community submitted about 120 ideas for the initial project, and on Nov. 22 the REF selected the mobile command post concept. A “Make-A-Thon” led to the creation of a mock-up vehicle in December. That mock-up was refined into a functional prototype that was completed Jan. 16 during a second Make-A-Thon event.

Pete Stephens, the Local Motors program manager for ArmyCoCreate, said the mobile command post took 55 days to complete. Discounting weekends and holidays, the vehicle task — from project selection to completion — involved 32 working days, he noted.

While the speed of development is impressive, a spokeswoman for REF emphasized that Army CoCreate is a proof-of-concept effort to test the applicability of crowdsourcing and related best practices, “for refining Army requirements and developing rapid solutions.” The REF, she added, continues to collect data and assess the proof of concept.

Still, such quick-turnaround projects could help the Army better meet the needs of soldiers in the field. Stephens, who comes from a defense contracting background, has previously worked on armored systems projects, some of which took five years to deliver.

“Soldiers’ lives are depending on our ability to get to the front faster,” he said.

Rapid prototyping

The crowdsourcing of tactical vehicles goes back to 2011, when the Defense Advanced Research Project Agency unveiled the Experimental Crowd-derived Combat Support Vehicle, or XC2V. DARPA, in a press release, referred to the XC2V as “the first crowdsourced, militarily relevant vehicle design.”

DARPA reported that more than 150 designs were submitted, noting that the chosen design took less than 14 weeks to construct. Local Motors built the XC2V prototype, which was designed to handle combat reconnaissance as well as combat delivery and evacuation missions.

The Army’s recent crowdsourcing venture focused on creating a Lightweight Tactical All Terrain Vehicle (LTATV) equipped with command, control, communications, computers, intelligence and reconnaissance (C4ISR) gear. The concept was to refit a Kawasaki Teryx 750cc LTATV to haul around the C4ISR capability.

The modification effort began at the December Make-A-Thon hosted at Fort Benning, Ga. Stephens said about 20 soldiers, mostly officers, participated. The first step was a one-day training and orientation exercise in which the participants used the ArmyCoCreate collaboration platform to come up with ideas for improving the process of filling sandbags.

After the orientation, the participants spent the next four days building a mock-up of the vehicle. The Make-A-Thon was live streamed to online participants who also contributed ideas. Stephens said one participant, an ultralight aviation enthusiast, provided insight on how to calculate the center of gravity when airlifting the vehicle under a helicopter.

Stephens said the mock-up was then shipped to Local Motors in Arizona for additional work and then returned to Fort Benning for the January Make-A-Thon.

The participants used an Army Expeditionary Lab, or Ex Lab, to build the mock-up. An Ex Lab is essentially a workshop in a shipping container that REF can deploy wherever equipment needs to be fabricated. Ex Labs come equipped with gear for rapid prototyping such as 3D printers.

The final step during the January Make-A-Thon was to add electronics, radios and 4G wireless capabilities to the prototype.

Challenges

Stephens said one of the biggest challenges of the mobile command post project was coming up with the right combination of soldier, maker and engineer participants. The degree of openness was another consideration. Local Motors’ open source business culture is a departure from the security-minded military environment.

“Our core business ... is open to the world; it is all open source design,” Stephens said. But with the military “we don’t want to get into a situation where we are compromising security.”

In addition, Stephens noted that rewarding and compensating the co-creation community might need some tweaking in the military setting. Local Motors offers cash prizes or trips to motivate participants for its non-military projects. The company’s main business is co-creating vehicles with a worldwide community of designers, engineers, fabricators and enthusiasts, according to the company.

Stephens said Local Motors offers cash prizes or trips to motivate participation. But with military projects, altruism has been the only motivational tool thus far.

“We need a better strategy than that,” he said.

In the meantime, Stephens said the mobile command post prototype is at a point where Local Motors could build a handful of additional vehicles and send them to a special evaluation unit at the front lines — should the Army make such a request. The rollout of a few vehicles for testing would provide an opportunity to further iterate the design, Stephens noted.