DLA orders modular 3D printing pod

The rugged 3D printing pod would be up to 40 feet long and housed in a standard shipping container so it could be deployed directly to the field to manufacture parts in support of battlefield operations, disaster relief or other remote missions.

The Defense Logistics Agency has ordered up a 3D printing factory housed in a shipping container.

Now under development, the rugged 3D printing pod would be up to 40-feet long and be set up in a standard 40-foot container so it could be deployed directly to the field to manufacture parts in support of battlefield operations, disaster relief or other remote missions.

With a $1.6 million contract to ExOne, DLA plans to use the company’s military-edition 3D printer for manufacturing products or tooling from over 20 metal, ceramic and other powder materials.

ExOne’s binder jet 3D printing is an additive manufacturing (AM) process that transforms powdered materials transforms into precision parts by using an industrial printhead to selectively deposit alternating layers of a liquid binder and powder particles.

Ideally, military personnel could use the 3D printing pod to turn a digital file of a broken or damaged part into a finished product in less than 48 hours, compared to the four to six weeks it currently takes to machine tool a new part, ExOne officials said. The process would also reduce waste and eliminate the need to carry expensive inventory into the field.

Rather than housing racks of spare parts in a storage depot, a digital library of 3D designs can be stored electronically. If a digital file is not available for older parts, the original item can easily be 3D scanned and printed. Additionally, service members can quickly design or modify parts and tools to solve unique problems.

The pod contains a 3D scanner and prep station, a ruggedized metal and ceramic binder jet 3D printer, a curing oven, a fiber-reinforced plastic 3D printer and a compression molding station. ExOne will also provide software and training so the pod can be used with minimal technical knowledge.

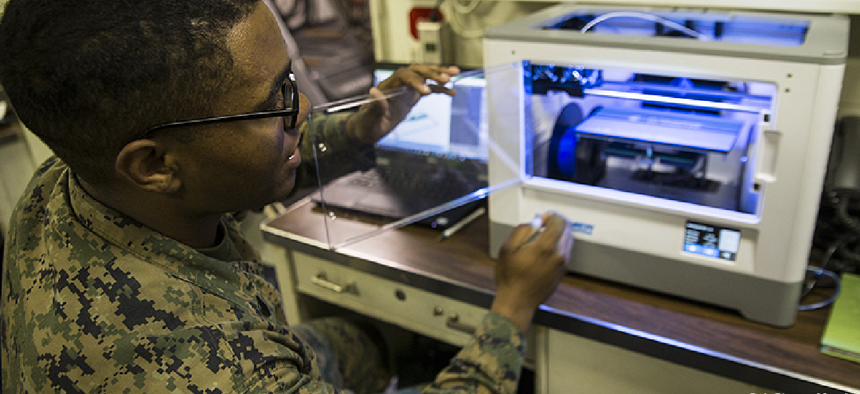

3D printing is starting to play a key role for the military. According to the Defense Department’s Additive Manufacturing Strategy, released in January, it is “a powerful tool to enable innovation and modernization of defense systems, support readiness and enhance warfighter readiness.”

A few forward-deployed additive manufacturing facilities have already been tested, including the Marine Corp’s X-Fab, a self-contained, 20x20-foot transportable shelter containing 3D printers, a scanner and computer-aided design software system; the AM Lab aboard the USS Stennis, which has been used to produce antenna parts and medical devices; and the Army’s Rapid Fabrication via AM on the Battlefield, a 24x20-foot workspace that contains five 3D printers.

To speed development of the rugged 3D printing pod for DLA, ExOne will collaborate with Dynovas Inc., which specializes in materials engineering, composites manufacturing and DOD weapons systems, and Applied Composites, a provider of complex composite components, assemblies, engineering and tooling to the aerospace, defense, and space systems markets.

“Binder jet 3D printing is a critical manufacturing technology for military use because of its speed, flexibility of materials, and ease of use,” said ExOne CEO John Hartner. “We’re excited to collaborate with the U.S. Department of Defense and other partners to make our 3D printers more rugged for the military, which will also benefit our other manufacturing customers. Most importantly, we know that years from now, our technology will play an important role in filling critical needs quickly.”

NEXT STORY: How robots would help the Post Office